Company

Company InformationMessage

MessageManabu Onogawa, Representative Director and President

Corporate Philosophy

Corporate Philosophy

Corporate Profile

Company Profile| Company name | Onogawa Co.,Ltd. |

|---|---|

| Representative | Manabu Onogawa, Representative Director and President |

| Established | April 1978 |

| Capital | 10 million yen |

| Settlement of accounts | August |

| Businesses | Manufacture of connectors (for automobiles, smartphones, and others); design and manufacture of production facilities and molds (pressing, plating, injection molding, and embossing) |

| No. of employees | 122 (as of April 1, 2020) |

| Office | ■Head Office, No. 1 Plant Iwaki Yotsukura Central Industrial Park, 1-23 Aza Yoshinosawa, Yotsukura Town, Iwaki City, Fukushima Prefecture 979-0201 Phone: 0246-32-4212 Fax: 0246-32-4210 ■No. 2 Plant Iwaki Yotsukura Central Industrial Park, 1-61 Aza Yoshinosawa, Yotsukura Town, Iwaki City, Fukushima Prefecture 979-0201 Phone: 0246-84-7461 Fax: 0246-84-7462 ■Vietnam Plant Scheduled to start operation in FY2020 (at Hai Duong) |

Access

Access~History~

History

【 Topix 】

We started business in 1978 with the assembly of automobile stereo audio systems, then commenced the assembly of various electronic equipment.| April 1978 |

Founded Onogawa Co.,Ltd. in Iwaki City, Fukushima Prefecture. (Capital: 5 million yen) Started assembling automobile stereo audio systems. |

|---|---|

| May 1984 | Started assembling hard disks. | May 1985 | Established a new plant (floor area of 200 m2). |

| May 1990 | Started mounting industrial printed boards. |

【 Topix 】

During our difficult times, we spotted connectors, which are electronic parts aligned in boards inside products. Triggered by one fortunate encounter, we started producing connectors, and our production volume increased steadily as the IT industry, including PCs and smartphones, grew.| July 1997 | Started manufacturing connectors for IT devices. |

|---|---|

| May 2000 | Started manufacturing automotive connectors. |

| August 2003 | Started assembling connectors for mobile phones (micro connectors). Micro connectors are narrow-pitch connectors of the world’s smallest class. |

| August 2004 | Started injection molding for micro connectors. |

| April 2005 | Started pressing for micro connectors. |

| April 2006 | Increased the capital to 10 million yen. |

| April 2007 | Established No. 2 Plant (floor area of 1200 m2). |

| December 2007 | Started operation of a new production system for micro connectors, with monthly production capacity of 10 million units. |

| May 2008 |

Established HQ Plant (floor area of 1500 m2) in Iwaki Yotsukura Central Industrial Park in Iwaki City, Fukushima Prefecture. (Boosted monthly production capacity to 20 million units.) |

| July 2008 | Started plating terminals for micro connectors. |

【 Topix 】

Our “connecting business” has kept evolving, and the auto industry too has entered a period of transformation toward the new era of safe and environmentally friendly vehicles. Vehicles equipped with automatic braking, electric vehicles, connected cars, autonomous driving, and maybe even flying vehicles in the future.| May 2009 | Started injection molding for automotive connectors. |

|---|---|

| June 2011 | Established Iwate Plant in Hachimantai City, Iwate Prefecture (in response to the Great East Japan Earthquake). |

| April 2013 | Started pressing terminals for automotive connectors. |

| March 2014 | Acquired certification under the quality management system ISO 9001:2008. |

| April 2015 | Won a quality award by achieving zero quality complaints for 3,650 days. |

| July 2016 | Established No. 2 Plant (floor area of 2400 m2) in Iwaki Yotsukura Central Industrial Park. |

| August 2016 | Started plating for automotive connectors. Started operation of a new production system for automotive connectors. |

| April 2018 | Acquired certification under the quality management system ISO 9001:2015.(Plan to acquire certification under IATF 16949 in FY2020.) |

| October 2020 | Established a subsidiary in Vietnam. |

| March 2021 | No. 2 Plant acquired certification under IATF 16949. |

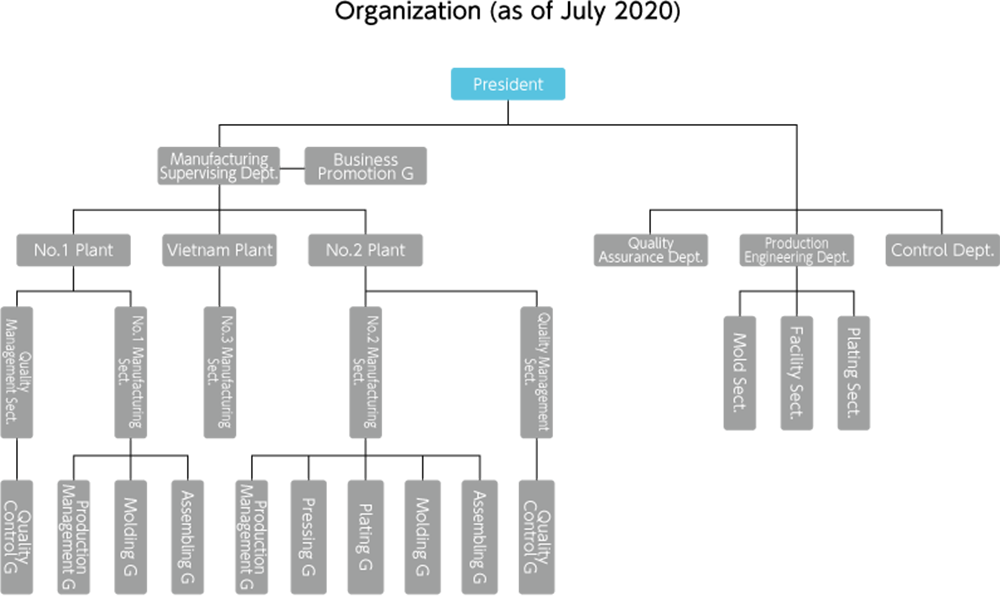

~Organization Chart~

Organization Chart

Please do not hesitate to contact us

if you have any questions.

phone.0246-32-4212

9 a.m. to 6 p.m. on weekdays